ClarkAUV

Navigating RoboSub, mapping seabeds, and monitoring underwater infrastructure. McGill Robotics’ ClarkAUV is the future of next-generation AUV. Built on the success of several years of team designs, the smallest and lightest McGill Robotics AUV to date. There’s nothing else like it

MeetUtility. Simplicity. Autonomy.

ClarkAUV 2.0

A New Era of McGill Robotics AUVs

Utility.

Simplicity.

Building upon our tradition of excellence, the ClarkAUV introduces a more lightweight design and modular mechanical design for effortless modification and improvement. We didn’t just improve upon the existing technology, we took it to a whole new level.

When we compare ClarkAUV to its previous version, it is undoubtedly in a class of its own. A key reason we’re so proud of this new design is its extraordinary ease of use. Whether we’re deploying pool-side or re-configuring electronics, ClarkAUV’s design allows us unparalleled accessibility.

Autonomy.

Welcome to the future of autonomous underwater operations. The sophisticated mission planner and advanced sensor array ensure optimal performance under competition conditions, paving the way for a new era in McGill Robotics AUV development. It's not just a step forward; it's a quantum leap in autonomy.

Clark2.0

Design. Test. Analyze. Repeat.

We champion iterative design, learning from failures, and continuous improvement. Our process begins with sketches, evolving into prototypes that pass through detailed reviews and dry-tests in simulations or labs.

Following successful testing, designs undergo pool tests with the AUV system, promoting cross-team collaboration and refinement.

ClarkAUV At A Glance

Degrees of Freedom

6 (Surge, Sway, Heave, Roll, Pitch, Yaw)

Embedded Systems

Arduino Uno Rev3 (Propulsion).

Arduino Micro (Pressure Sensor)

Power System

Custom Power Governance PCB.

14.8V 20000mAH BlueRobotics LiPo Battery

Compute Module

NVIDIA Jetson AGX Orin

Navigation Stack

SBG Elipse-N IMU

Water Linked A50 DVL

Custom Pressure Sensor

Propulsion

BlueRobotics T200 Thrusters and Electronic Speed Controllers (x8)

Software Stack

Robotics Operating System (ROS) Noetic

Ubuntu 20.04 LTS

Python3, C++, C

Machine Learning

PyTorch

YOLO v8

Computer Vision

Intel RealSense d455 (Forward Facing)

Arducam IMX219 Camera Module

Clark2.0

Software Stack

At the core of our AUV's innovative software design: Planner orchestrates high-level decisions, Vision employs machine learning for object detection, State Estimation ensures real-time precision, and Propulsion optimizes movement. Our Gazebo-based simulation with realistic hydrodynamics enables us to rapidly test and tune our code in a pool-like environment.

Clark2.0

Electrical Architecture

Re-wiring what’s possible for university-level design: Our high-caliber power board delivers robust protection and efficient energy distribution, seamlessly driving the entire AUV from a PCB smaller than an iphone.

The Sensor Board, a crucial communication hub, interfaces with multiple sensors for optimal data processing. Together, they streamline wiring, enhance safety, and enable real-time decisions - a testament to the unrivaled autonomy and performance of our AUV.

Clark2.0

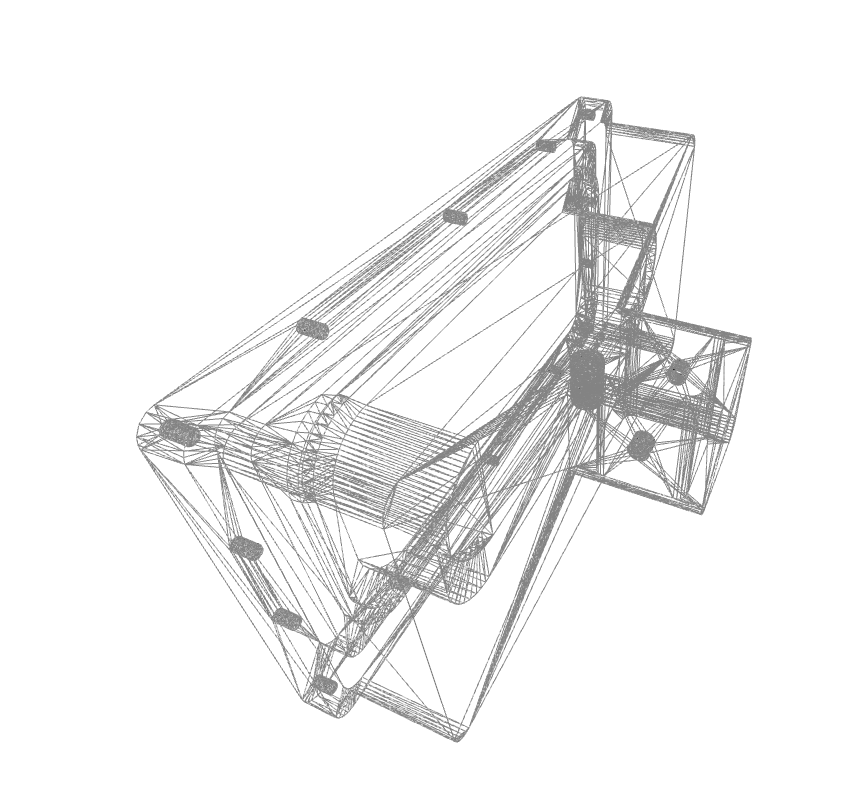

Mechanical Design

Robust mechanical design meets elegant UI/UX principles: this year we revamped the previous version of Clark to optimize for flexibility, starting with a reimagined chassis that merges symmetry with stability and flexibility, using stainless steel cubes and T-slotted framing. Our streamlined propeller positioning optimizes movement control, housed in a robust, sealed acrylic hull, featuring a sliding shelf for quick electronics access. We've ingeniously overhauled the internal layout with a new sled mechanism, ensuring straightforward access to our PCBs and electronics.

Clark2.0

Team Behind The Machine

Over the course of an entire school year, our team of talented engineers has worked tirelessly to produce the AUV representing our team at this year’s RoboSub. Spanning three different sub-divisions of Mechanical, Electrical, and Software, the more than 20 students who bonded together to develop and design ClarkAUV 2.0 are truly some of the most dedicated and exceptional students that McGill has to offer.