Cost-Effective Quadplane:

A comprehensive testing platform

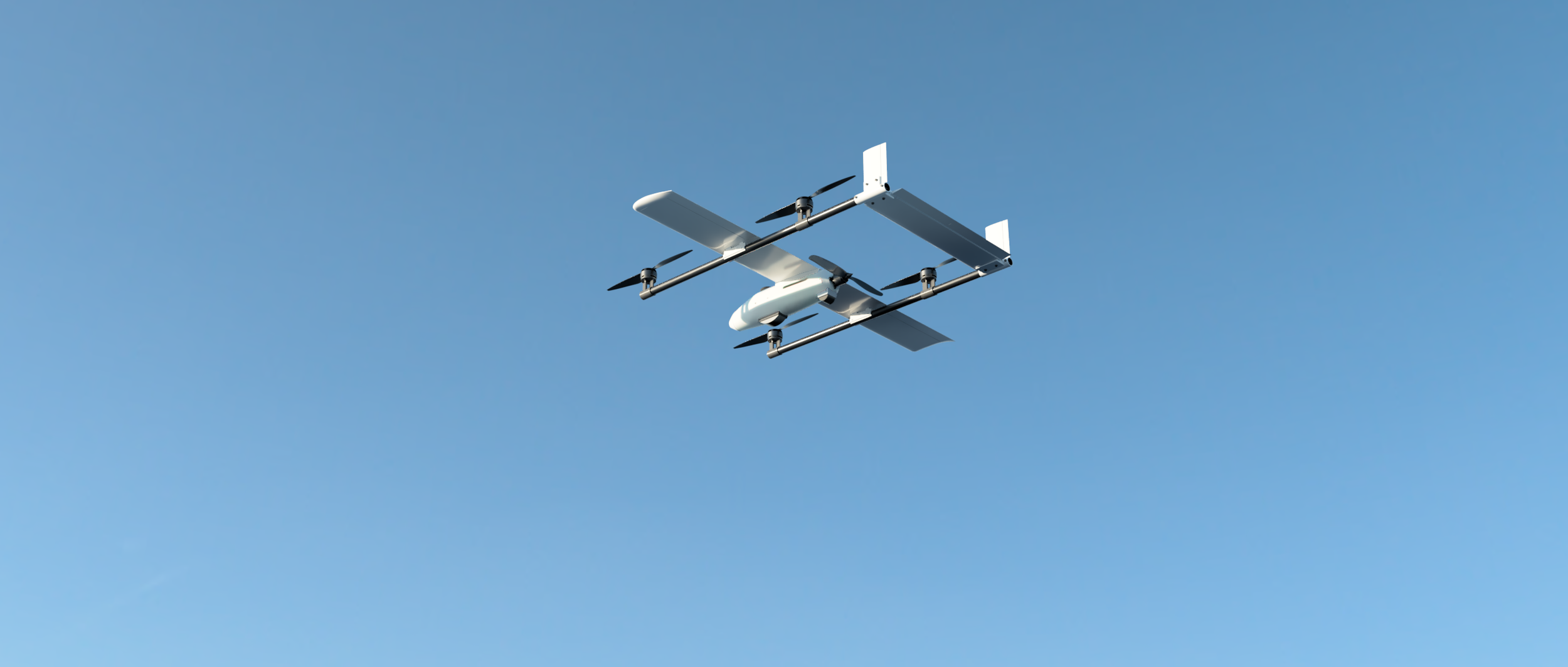

Mini Millie

The Mission.

Developed for the McGill Robotics drone team, this cost-effective and repairable Quadplane enables student teams and resource-limited labs to safely develop and test VTOL transition controllers, while avoiding the risk of damaging valuable aircraft during early-stage experiments.

<48hr

Build from Scratch

15

Mechanical fuses

8

Crashes - 0 damage

The Project at a Glance

Crash-Resilient

Sacrificial components absorb 125N+ impacts

8 uncontrolled crashes, 0 damaged electronics

Rapid-Repair

Tool-free 3D-printed snap fits for field maintenance

Magnet-secured wingbox detaches under overload (>100N)

Standardized repair benchmarks: 10–30 min per failure mode

Transititon-Test Focus

Inverted pusher motor minimizes airflow disruption

PX4 telemetry logs spike events for software tuning

Yaw stability data informs flight controller limits

Weight-Optimized Structures

NACA 7415 wings with dual-spar drill-tip

3D-printed PETG fuselage with internal lattice bracing

XPS foam core wings

Safety Integration

Wingtip-embedded anti-collision lights

Galvanic-isolated nylon inserts in booms

Triple-constraint vibration-resistant mounts

Academic Accessibility

$1100 total build cost

Open-source flight controller templates

Designed for 50+ crash/repair cycles

3rd Place at Engine Entrepreneurship Competition

-

Test

-

Validate

-

Learn

Performance Metrics

Design Specifications

MTOW: 12kg

Cruise Speed: 25 m/s

Total Cost: $1,100 CAD

Autonomy: 15 mins

Airfoil: NACA 7415

Turnaround Times

From Scratch: 48 hours

Wing Fracture: 20 mins

Sacrificial Part Failure: 10-30 mins

Aerostructure replacement: 20 mins

Meet the Team